Backflow prevention might not be the most exciting topic, but it’s crucial for ensuring that the water we use daily remains clean and safe. Imagine the inconvenience of turning on your faucet and instead of fresh, clean water, you get contaminated water that could pose serious health risks. This scenario underscores the importance of backflow prevention systems, which are designed to keep our water supply safe from contamination. In this blog, we’ll dive deep into why backflow prevention is essential for safety, exploring how it works, common issues, and tips for maintaining a reliable system.

What Is Backflow?

To understand why backflow prevention is crucial, let’s first define what backflow is. Backflow happens when water reverses its normal direction and flows backward into the clean water supply. This reversal typically occurs due to a sudden drop in water pressure within the system, often caused by issues such as a burst pipe or high water demand. When the pressure drops, it can create a vacuum effect, drawing water from a potentially contaminated source back into the potable water system.

This backward flow can lead to cross-contamination, where harmful pollutants or chemicals enter the clean water supply. Such contamination poses significant health risks, making backflow prevention essential for maintaining safe and clean drinking water.

Types of Backflow

Backsiphonage

Backsiphonage occurs when a drop in water pressure within the main supply system causes water to flow backward from a contaminated source. This often happens during events such as a water main break or periods of high water demand, creating a vacuum that pulls unsafe water into the clean supply.

Backpressure

Backpressure happens when the pressure in a private system, such as a pump or boiler, exceeds the pressure in the public water supply. This higher pressure can push contaminated water from the private system back into the clean water supply, leading to potential contamination and health risks.

Why Backflow Prevention Is Essential

Now that we have a basic understanding of backflow, let’s explore why preventing it is so crucial:

Protecting Public Health

The primary reason for backflow prevention is to safeguard public health. Contaminated water can carry harmful bacteria, viruses, and chemicals that can cause severe illnesses or even outbreaks of diseases. By preventing backflow, we ensure that our water supply remains free from these hazards.

Preventing Contamination of Drinking Water

Our drinking water is treated and tested to meet safety standards before it reaches our homes. Backflow can introduce pollutants into this water, nullifying the treatment process and putting everyone who consumes the water at risk.

Avoiding Legal and Financial Repercussions

Many regions have strict regulations regarding backflow prevention to ensure the safety of the water supply. Failing to comply with these regulations can lead to fines, legal issues, and increased costs for water treatment and cleanup.

Maintaining Water Quality

Backflow prevention systems help maintain the overall quality of the water supply, ensuring that it remains safe and clean for all users. This is particularly important in areas with high levels of industrial or agricultural activity, where the risk of contamination is greater.

Protecting Your Property

Backflow prevention not only protects public health but also safeguards your property. Contaminated water can cause damage to plumbing systems, appliances, and other property components, leading to costly repairs and replacements.

How Backflow Prevention Works

Backflow prevention systems are designed to ensure that water flows in the correct direction, preventing contamination from entering the potable water supply. These systems typically include a variety of devices and mechanisms:

Check Valves

These valves allow water to flow in only one direction. If water tries to flow backward, the valve closes to prevent it from entering the clean water supply.

Air Gaps

An air gap is a physical separation between the end of a water pipe and the highest point of the sink or faucet. This gap prevents backflow by ensuring that there is no direct connection between the water supply and any potential contaminants.

Backflow Prevention Assemblies

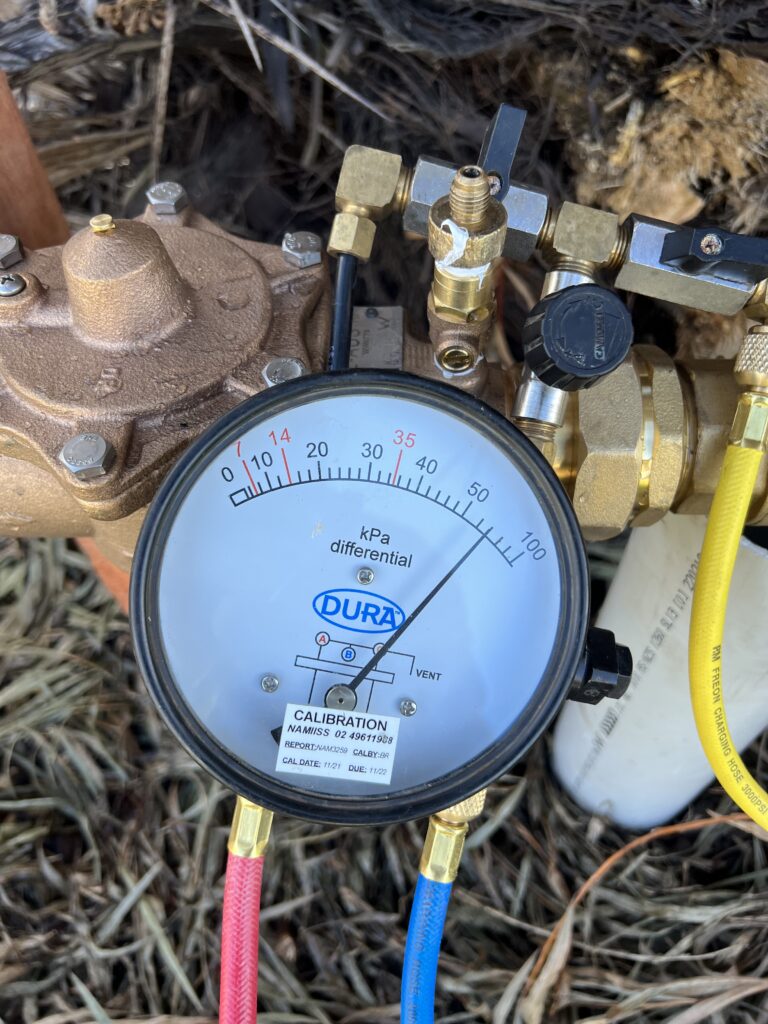

These assemblies combine multiple devices, including check valves and shut-off valves, to create a comprehensive backflow prevention system. They are often used in high-risk areas or where critical contamination risks exist.

Common Backflow Prevention Devices

Several types of backflow prevention devices are commonly used, each suited for different situations:

- Single Check Valve: This is the most basic type of backflow prevention device. It allows water to flow in one direction and closes to prevent backflow. It’s suitable for low-risk situations.

- Double Check Valve Assembly: This device includes two check valves in series, providing an added layer of protection. It’s used in moderate-risk situations where additional security is needed.

- Reduced Pressure Zone (RPZ) Valve: The RPZ valve is a more complex device that includes two check valves and a pressure relief valve. It’s designed for high-risk situations and provides the highest level of protection against backflow.

- Pressure Vacuum Breaker (PVB): This device is commonly used in irrigation systems. It includes a valve that opens to allow air in if backflow occurs, preventing water from flowing backward.

Common Backflow Prevention Issues

Improper Installation

Backflow prevention devices need precise installation to operate correctly. If installed incorrectly, these devices may develop leaks, experience malfunctions, or fail entirely. Proper installation ensures that the device functions as intended, preventing potential contamination and maintaining the integrity of the water supply.

Lack of Maintenance

Regular maintenance is crucial for backflow prevention devices to function effectively. Without routine checks, these devices can develop issues like valve failures or clogged components, compromising their ability to prevent contamination. Routine upkeep helps ensure that the system remains reliable and effective.

Cross-Connections

Cross-connections occur when a non-potable water source is improperly linked to the potable water supply. Such connections can introduce contaminants if not managed correctly. Preventing cross-connections involves ensuring proper separation between clean and contaminated water sources to maintain water safety.

Wear and Tear

Backflow prevention devices endure gradual wear and tear over time, which can diminish their effectiveness. Regular inspections and timely replacements of worn-out parts are essential to maintain the device’s performance and ensure continued protection against water contamination.

Tips for Maintaining Backflow Prevention Systems

To ensure your backflow prevention system remains effective, follow these maintenance tips:

Regular Inspections

Schedule regular inspections by a certified professional to thoroughly assess your backflow prevention system. These experts can detect early signs of potential issues, such as leaks or malfunctions, allowing for timely repairs before they escalate into more serious problems, thereby ensuring continuous protection.

Perform Routine Maintenance

Adhere to the manufacturer’s guidelines for routine maintenance of your backflow prevention system. This includes regular cleaning and replacing worn-out parts as necessary. Proper maintenance helps keep the system functioning efficiently, reducing the risk of failures and ensuring the ongoing safety of your water supply.

Test Your System

Conduct regular tests on your backflow prevention device to verify that it operates correctly. Many devices have specific testing protocols that need to be followed. Regular testing helps identify any performance issues early and ensures the device consistently prevents contamination.

Check for Cross-Connections

Regularly inspect your plumbing system for any cross-connections between potable and non-potable water sources. Address any identified cross-connections promptly to prevent contaminants from entering the clean water supply, ensuring the safety and quality of your water.

Stay Informed

Stay updated on local regulations and best practices for backflow prevention. Knowledge of current codes and guidelines helps you remain compliant and implement effective prevention measures. This vigilance ensures that your system continues to provide optimal protection against water contamination.

Conclusion

Backflow prevention is essential for ensuring the safety and quality of the water supply. Understanding the risks of back siphonage and backpressure, and addressing issues like improper installation, maintenance neglect, cross-connections, and wear and tear can effectively safeguard against contamination. Regular inspections, maintenance, and testing are crucial to keeping the system functioning properly. For reliable backflow prevention services in Valley Bay, AU, contact EZI Plumbing at 0448467788. Prioritize backflow prevention and protect the water supply today.